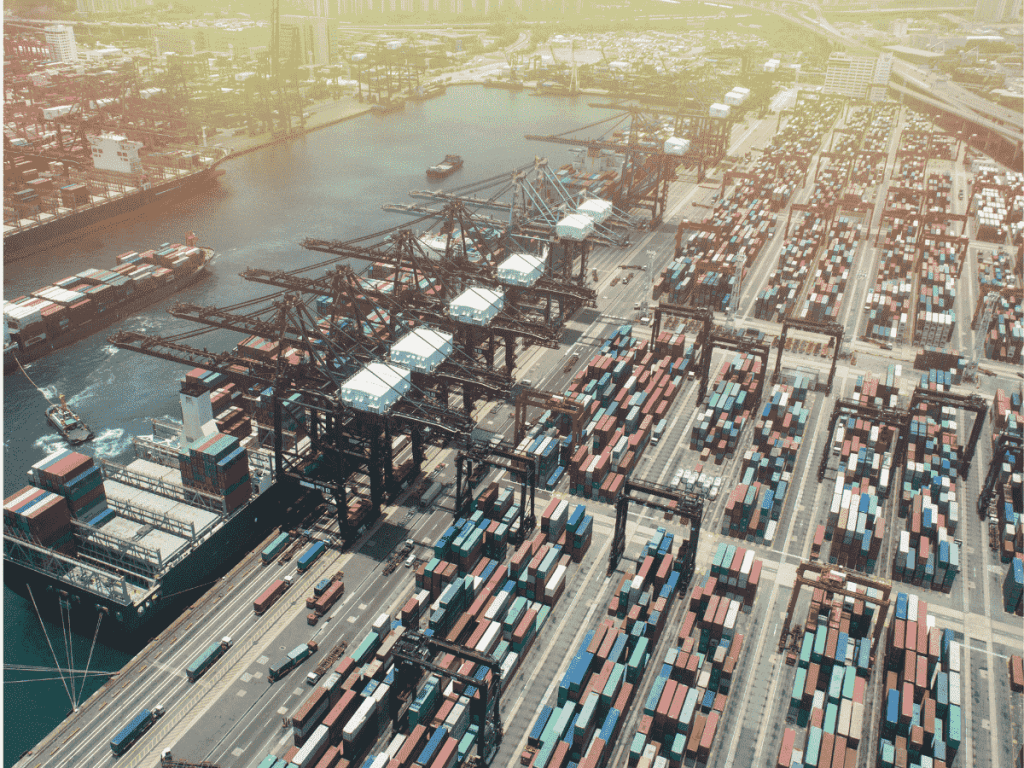

The last few years have been one historical event after the next – a horrifying pandemic, climate catastrophes, a war, an economic collapse, and so much more. Somewhere in between this, the supply chain solutions system have taken a massive hit and disruptions have shaken the already fragile world.

It has been two years since the supply chains began to experience disruptions and resiliency gaps became more glaring – two years since the pandemic started wreaking havoc on trading systems, warehouse vacancies, carrier reliability, rates of freight movement, etc.

Supply Chains are not ready for Climate Change

Climate change does not bode well for anyone on this planet. For supply chains, it means disruptions

in shipment, delayed deliveries of essential goods, damage to freight shipping and equipment worth billions,

and many other unexpected problems.

When the 2019-20 Bushfires blazed misery in several parts of Australia, the country was not

prepared for the environmental and economic loss it had to suffer. Climate change has made the

weather unpredictable, lowering the ability of meteorologists to forecast the next big catastrophe to

promote preparedness and mitigation strategies.

So long as this continues, supply chain systems will be at the mercy of the climate.

The Issues Always Hid in Plain Sight

It would be a lie to claim that the global supply chain functioned smoothly before 2020. There were

problems and inefficiencies, but their spill-over impact was usually contained to a few points in the

chain. All that the pandemic did was magnify these issues and the supply chain fell like a stack of

dominos. The magnitude of these problems was too huge to go unnoticed after that year. On one

hand, inventories kept piling up due to a lack of shipment containers, and on the other hand,

manufacturers kept waiting for the delivery of their intermediates or inputs to complete production.

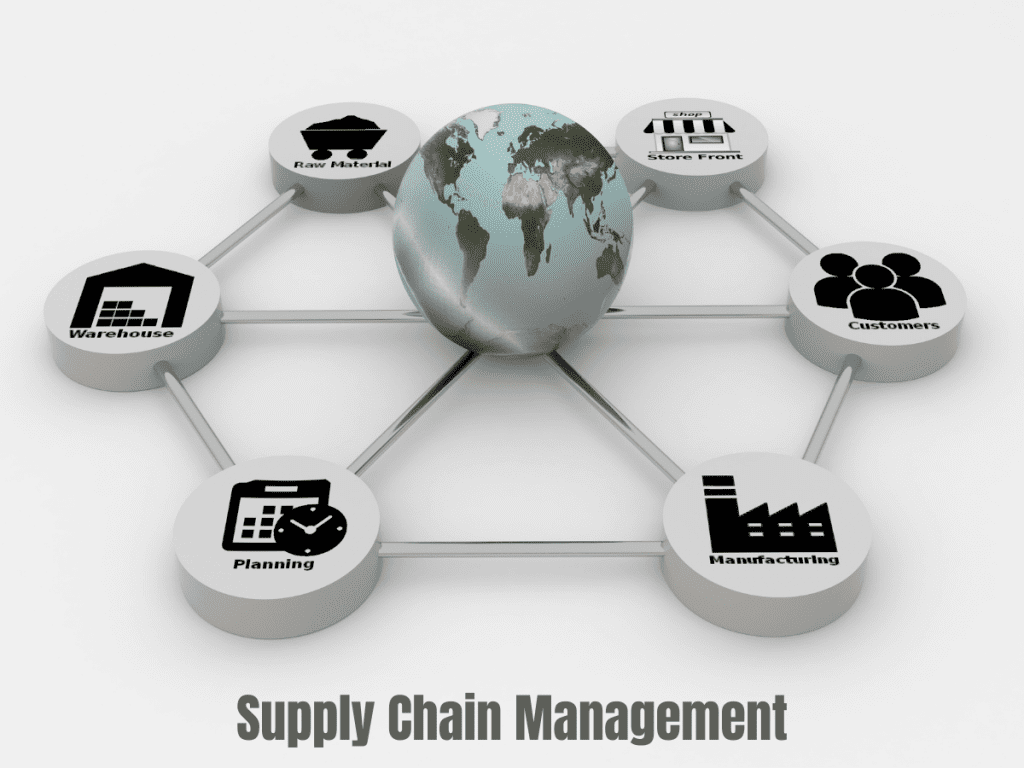

The Gaps Between Speech and Action are Finally Decreasing

Before the pandemic forced lockdowns all over the globe, supply chain sustainability and resilience were a mere talk shop. But now, industries and other stakeholders are taking matters into their own

hands, innovating new techniques, and devising smart strategies to make supply chains stronger in

the face of unprecedented and unpredictable challenges.

Many of the global companies have already invested in research for new technologies and a

significant number of others have shown interest and are contributing in the ways they can. It is no

more the time to sit back and let others find the solutions, but take the reigns in your hands and

start the cycle of change.

The Future Relies on Digitization and Risk Management

It is the age of digitization, Internet of Things, and Artificial Intelligence. The best answers to supply

chain problems and mitigating risks can be found through these new-age technologies. Capitalizing

on the Fourth Industrial Revolution to find state-of-the-art supply chain solutions can be one of the

best shots industry stakeholders can take right now.

The pandemic lost its momentum gradually and the world tried to accommodate to the new normal.

Supply chain management, on the other hand, remains suspended in the air, hanging by a thin

thread from falling into the abyss. One might think of this as an exaggeration but a single glance at

any major economic publication’s opinion on SCM will clear any doubts.

The last two years have made it exceedingly obvious that the global supply chain system is riddled

with problems and inadequacies. But where there has been unveiling of issues, there has also been a

newfound zeal to overcome these shortcomings and make the supply chains more resilient than

ever.